Improving your operational efficiency is really just about finding smarter ways to work. It’s about getting more done—whether that's serving more customers or producing more widgets—using the same, or even fewer, resources. Think of it as eliminating the friction in your daily operations to boost both productivity and your bottom line. But before you can start fixing things, you have to get a crystal-clear picture of where you stand right now. That journey starts with an audit.

Auditing Your Current Operations

Before you can make any meaningful changes, you need to know exactly what’s happening on the ground. Think of an operational audit not as a fault-finding mission, but as a fact-finding one. The goal is to create a detailed map of your current reality. This map gives you the hard data you need to justify changes and, later on, to prove they actually worked.

This isn't about a quick glance at a few performance dashboards. It's a deep dive into the nitty-gritty of your business, from how an order gets from a customer's click to their doorstep, to the way you bring a new hire into the fold. Without this clarity, any attempt to improve efficiency is just a shot in the dark.

Map Your Core Processes

The first real step is to get your workflows down on paper. Process mapping is all about documenting every single step of an operation, from beginning to end. And I don't mean a high-level summary; I'm talking about a granular, step-by-step breakdown.

Take something as common as "invoice processing." A proper map would include details like:

- Receipt: How do invoices arrive? Email, snail mail, a vendor portal?

- Data Entry: Who is responsible for keying the data into your accounting software?

- Approval: What’s the chain of command for getting it approved? Does a $50 invoice go through the same process as a $5,000 one?

- Payment: How are payments scheduled and sent?

- Filing: Where does the final record live?

Laying it all out visually makes the bottlenecks, redundant steps, and clunky handoffs jump right off the page. You might quickly see that invoices languish in an inbox for days, or that a multi-level approval process for tiny expenses is a huge time-waster. These are the kinds of hidden problems that quietly bleed your resources dry.

Key Takeaway: You can't fix what you can't see. Process mapping turns invisible workflows into tangible diagrams, exposing the logjams and improvement opportunities that are impossible to spot in the day-to-day rush.

Get Honest Feedback From Your Team

Let's be real: your frontline employees are the true experts on your processes. They live with the workarounds and daily frustrations. If you want the real story, you have to create a space where they feel safe sharing it.

Skip the formal surveys, which often yield generic answers. Instead, go for more direct, human methods.

Try holding small, informal focus groups or even do a few one-on-one "ride-alongs," where you just shadow an employee for an hour to see their workflow in action. Ask open-ended questions like, "What's the most annoying part of this task?" or "If you had a magic wand, what's the one thing you'd change about how this gets done?"

This is how you uncover the insights that data alone will never show you. You might learn, for instance, that a team member spends 30 minutes every single day manually reformatting a report simply because two of your software systems don't talk to each other. That’s a glaring, easily fixable opportunity for automation.

Benchmark Where You Are Today

Once you've mapped the process and talked to your team, the final piece of the audit is putting some hard numbers to it. This means identifying a few key performance indicators (KPIs) and measuring them. You can compare these numbers to industry standards or just your own past performance. Benchmarks give you context and help you set achievable goals.

A few great metrics to start with are:

- Cycle Time: How long does it take to complete a process from start to finish? (e.g., from the moment a customer places an order until it’s shipped).

- Cost Per Unit: What’s the total all-in cost to produce one item or deliver one service?

- Error Rate: What percentage of outcomes have mistakes or need to be redone?

- Throughput: How much work gets done in a set period, like a day or a week?

With these concrete numbers, your efficiency initiatives stop being vague ideas and become measurable projects. Instead of saying, "We need to ship things faster," you can set a data-driven goal: "Our mission is to cut our order fulfillment cycle time from 48 hours to 24 hours in the next quarter." This is how you track real progress and prove the value of your hard work.

Getting Your Team in Sync for Peak Performance

Once you’ve mapped out your processes, it's time to turn your attention to the people who bring them to life. Your team is the engine of your entire operation. But even a finely tuned engine can't perform if the parts aren't working together or if it's not properly maintained. Optimizing your team isn't just about headcount; it’s about making sure you have the right people in the right roles, armed with the right skills to do their best work.

True operational efficiency improvement comes from empowering your people, not just managing them. It’s a deliberate effort to match individual talents with what the business actually needs. When you get this right, you don't just see a bump in productivity—you get a more engaged and motivated team that drives real growth.

Are Your Workloads Secretly Sinking Productivity?

Nothing kills morale and efficiency faster than an unbalanced workload. It's a quiet problem that quickly breeds resentment and burnout when one person is completely swamped while another has pockets of downtime. To fix this, you first need a clear, honest picture of who is doing what.

Have your team track their time for a week or two. This isn't about playing Big Brother; it's about collecting objective data. You'll be surprised by what you find. I’ve seen situations where a senior developer was spending 25% of their week on basic administrative updates—work that could have easily gone to a junior team member, freeing up that high-value expertise.

Once you have the data, you can start to rebalance things. Look for opportunities to:

- Shift routine tasks: Move simpler, repetitive work from senior staff to junior employees who are eager to learn and grow.

- Cross-train your people: Teach team members how to handle some of each other's core tasks. This builds in flexibility for when someone is sick, on vacation, or just buried under a deadline.

- Automate the obvious: Find those low-skill, mind-numbing tasks that software can handle, freeing up your team for work that requires a human brain.

An overworked employee is an inefficient employee. Period. By making sure workloads are fair and manageable, you're not just preventing burnout; you're building a more resilient and agile team.

Find and Fix Your Team’s Skill Gaps

Your business doesn’t stand still, and neither can your team's skills. A skill gap analysis is simply a structured way of comparing the skills your team has with the skills your business needs to hit its goals. This isn't about calling people out; it's about building a clear roadmap for professional growth.

For example, I once worked with a marketing agency that wanted to offer high-end data analytics, but they had a big problem: only one person on the entire team knew how to use their data visualization tools. That’s a massive risk. What happens if she leaves?

Identifying the gap is the easy part. Closing it is what matters. You don't always need to send people to expensive, off-site training. Think about:

- Peer mentoring: That one expert on the team? Have them run a few lunch-and-learn sessions for their colleagues.

- Online courses: Give your team access to platforms that let them learn at their own pace.

- Sponsoring certifications: Invest in your employees by helping them get certified in high-demand skills that are directly relevant to your business.

This isn't just a "nice-to-have." According to recent data from Mercer, 51% of executives are focusing on employee upskilling and reskilling to boost productivity. Another 44% are zeroing in on workflow optimization, which shows you just how connected people and processes are. This focus naturally extends to hiring, where finding people with niche skills—like those needed for automated speech recognition services—can give you a serious competitive edge.

When you proactively address skill gaps, you build a more capable and self-sufficient team. You reduce your reliance on outside hires for every new challenge and empower the people you already have to take on more valuable work, which flows directly to your bottom line.

Weaving Automation and AI into Your Workflows

Once you've aligned your team structure and sharpened their skills, the next big leap in operational efficiency improvement comes from bringing in the right technology. Automation and Artificial Intelligence (AI) aren't just for the big players anymore; they are accessible tools that can fundamentally change how work gets done. Think of them as a force multiplier for your team.

The real goal here isn't about replacing people. It's about empowering them. By handing over the monotonous, repetitive tasks to technology, you free up your team's brainpower for what really matters: strategic planning, creative problem-solving, and building genuine customer relationships. That's where your true business value lies.

Spotting the Prime Candidates for Automation

Not every process is a good fit for automation, and trying to automate everything at once is a recipe for disaster. The trick is to start with the low-hanging fruit—those simple, repetitive, high-volume tasks that give you a quick win and build momentum.

Look for workflows with these tell-tale signs:

- High Volume and Repetitive: Think of tasks done the exact same way, over and over, like processing standard invoices or entering new customer data.

- Rule-Based: These are processes that follow a strict "if this, then that" logic. Computers are brilliant at following rules perfectly every single time.

- Prone to Human Error: Any workflow that involves a lot of manual data entry or copying and pasting is a prime target. A bot doesn't get tired or make typos.

- Time-Consuming but Low-Value: Consider the tasks that eat up hours in a day but don’t require a shred of critical thinking.

A classic example I see all the time is in accounts payable. The manual grind of entering invoice details, matching them to purchase orders, and routing them for approval is a perfect storm of these traits. Automating just this one process can claw back hundreds of hours a year and virtually eliminate payment errors.

"A significant trend in operational efficiency improvement is the increasing adoption of automation technologies. Organizations that embraced automation tools such as Robotic Process Automation (RPA) have been able to drastically reduce time spent on repetitive tasks, minimize human error, and increase consistency in operations."

Getting Your Data Ready for AI

Here’s a hard truth: automation tools, especially AI, are only as good as the data you feed them. If you give them garbage, you'll get garbage out. It's that simple. That's why prepping your data isn't just a recommendation; it's a non-negotiable first step.

Getting your data "AI-ready" boils down to a few core tasks:

- Standardization: Make sure all your data speaks the same language. For instance, all dates should be in the same MM/DD/YYYY format, and state names should use consistent abbreviations (e.g., "CA" not "Calif." or "California").

- Cleaning: This is the nitty-gritty work of finding and fixing (or removing) incorrect, corrupted, or duplicated data. An AI can't give you accurate customer insights if it thinks "John Smith," "J. Smith," and "Johnathan Smith" are three different people.

- Centralization: Your data can't be scattered across a dozen disconnected spreadsheets and old software. Pulling it into a central place, like a data warehouse, makes it accessible and ready for your AI tools to analyze.

You can learn more by exploring our detailed guide on business process automation.

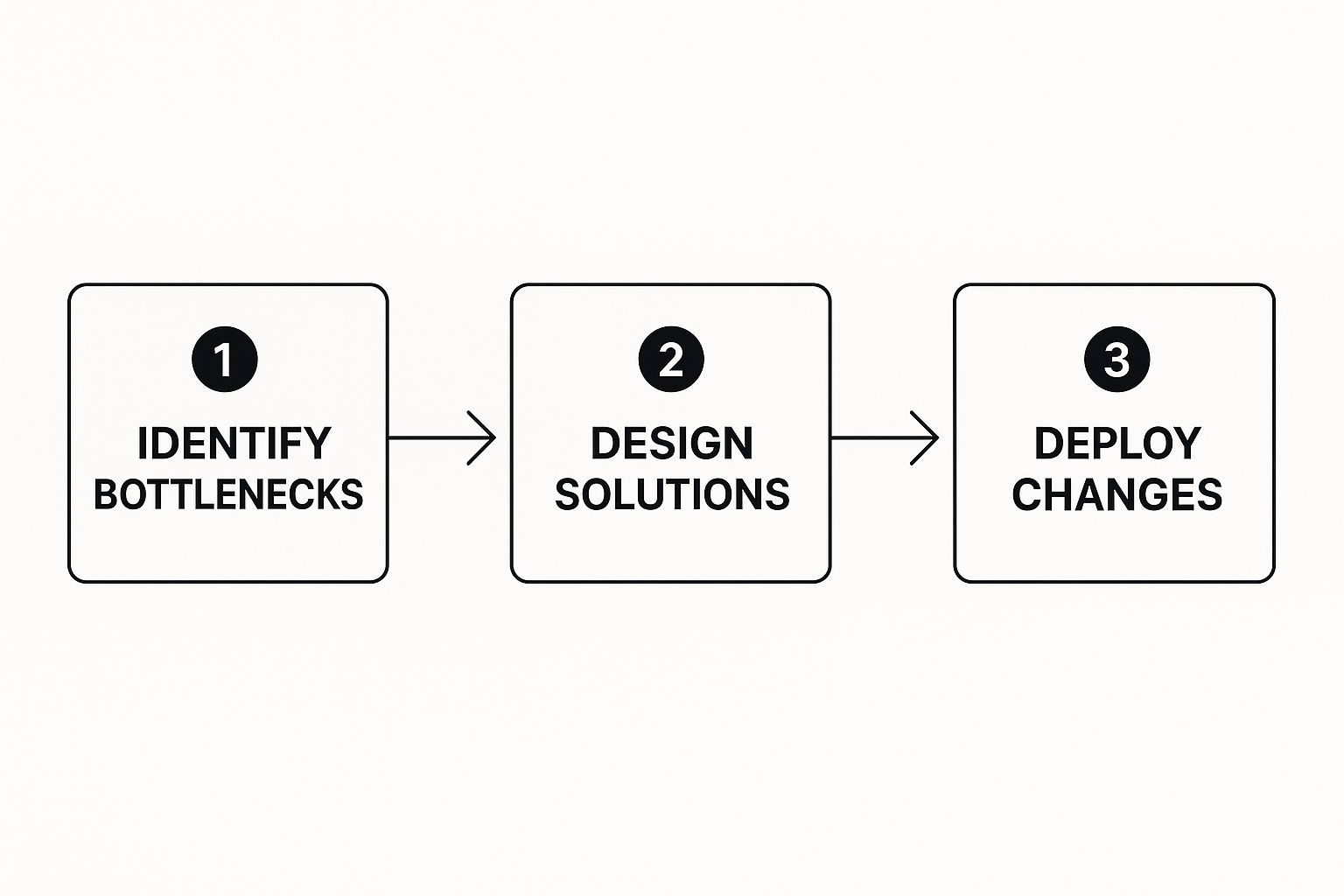

This infographic provides a simple framework for finding these opportunities and putting the right solutions in place.

As the visual shows, success comes from a deliberate process: pinpoint a specific problem, then design a targeted tech solution to solve it. Taking the time to get your data house in order upfront saves you from massive headaches later and ensures your new tools deliver the reliable results you expect.

To dig deeper into what this technology can do for your business, check out this excellent read on the potential of AI in business.

Redesigning Processes Without Disrupting Business

Spotting a clunky workflow is the easy part. Actually changing it without grinding your entire operation to a halt? That’s where the real challenge lies. The fear of causing chaos often keeps great ideas stuck on the whiteboard, but it doesn’t have to. With a smart, phased approach, you can make these transitions surprisingly smooth.

The secret is to stop thinking about process redesign as a massive, top-down overhaul. Instead, treat it like a collaborative experiment. Rather than flipping a switch and praying it works, you roll out changes in controlled, manageable stages. This approach dramatically lowers your risk, gets your team on board, and ensures the new process is ready for the real world before it goes live.

Start Small with Pilot Programs

Diving headfirst into a company-wide change is a recipe for disaster. A much safer—and smarter—bet is to run a small pilot program first. Think of it as a beta test for your new workflow. Just grab one team or one isolated part of the process and use them as your testing ground.

Let's say you want to bring in a new project management tool to get communication under control. Instead of making everyone switch at once, pick a single project team and have them use it for their next two-week sprint. You’ll get immediate, real-world feedback on what works and what doesn't.

This gives you a few major wins:

- A Low-Risk Sandbox: If the new process flops, the damage is contained to a small group and is easy to fix.

- Real Data, Not Guesses: You'll collect actual performance metrics, which are far more convincing than any theoretical benefits you pitched.

- Honest Feedback: The pilot team becomes your best source for practical, unfiltered advice on how to make it better.

This small-scale test lets you prove the concept and tweak it based on reality, not just your initial plan.

Create Clear Documentation and Communicate Effectively

Once your pilot has helped you iron out the wrinkles, your next job is all about communication. People won't get behind a new way of working if they don't understand it. Vague announcements just breed confusion and pushback.

You need to be direct and transparent. Start by acknowledging the pain points everyone is already familiar with. Then, show them exactly how the new process solves those specific problems. For example, "Remember all the complaints about double data entry for client reports? This new system automates that, which should give each of you back about three hours a week."

My Pro Tip: Don't skimp on documentation, but keep it simple. Nobody wants to read a 50-page manual. A one-page cheat sheet, a quick video tutorial, or a simple checklist is far more effective. It makes the new process feel approachable and lets people learn on their own terms.

Establish Continuous Feedback Loops

Rolling out a new process isn't the end of the project—it's the beginning. To make sure the change actually sticks and keeps delivering results, you absolutely must have ongoing feedback loops in place. This turns a one-and-done implementation into a system that keeps getting better.

Make it incredibly easy for people to share their thoughts. Set up a dedicated Slack channel, a simple Google Form, or just carve out five minutes in your weekly team meeting for it. Ask targeted questions, like, "What was the most frustrating part of the new workflow this week?" or "Did the new tool actually save you time like we hoped?"

When you actively ask for and act on feedback, you send a powerful message: your team's experience matters. This not only helps you smooth out any lingering issues but also builds a culture where everyone is invested in operational efficiency. When people see their suggestions being put into action, they stop being resistant and start becoming champions for the change.

Measuring Success with the Right KPIs

After you've put in the hard work of redesigning your processes, the big question looms: "Did any of it actually work?" Answering that takes more than just a gut feeling. You need a way to track your progress with cold, hard data.

This is where Key Performance Indicators (KPIs) come in. They're the scoreboard for your operational efficiency efforts. Without them, you're flying blind, unable to prove the value of your changes or pinpoint what still needs a little work. The goal is to move past simple "vanity metrics" and focus on numbers that truly reflect the health of your operations.

Identifying KPIs That Truly Matter

First things first, you have to pick the right metrics. The best KPIs are always directly tied to the specific process you just improved and the broader business goals you’re chasing. What’s critical for a manufacturing line, for example, will look completely different from what a customer support team needs to track.

Don't try to track dozens of data points. That just creates noise. Instead, pick a handful that tells a clear, compelling story.

Here are a few of the most impactful operational KPIs I've seen deliver results:

- Cycle Time: This is the total time it takes to get something done from start to finish. Think from the moment a customer places an order to the second it's shipped. Shorter is almost always better.

- Throughput: Put simply, this is how much work you get done in a set period. It could be the number of support tickets closed per day or widgets produced per hour.

- Cost Per Unit: This one is a direct line to your financial efficiency. It calculates the total expense to produce one single product or deliver one service.

- Error Rate: This tracks the percentage of outcomes that have mistakes or need to be redone. Nudging this number down is one of the most powerful ways to slash waste and boost quality.

Choosing your metrics carefully is the foundation for making smart, informed choices. If you want to go deeper, check out our guide on how to implement data-driven decision-making in your business.

Bringing Your Data to Life with Dashboards

Let's be honest: raw data in a spreadsheet is a pain to interpret and even harder to get anyone excited about. This is why a good visual dashboard is an absolute game-changer. Dashboards turn your KPIs into charts and graphs that are simple to understand, making it easy to spot trends, check progress, and share your wins with the whole team.

A great dashboard is clean, intuitive, and focused. It should answer key questions at a glance, like "Are we hitting our targets?" or "Where's the new bottleneck?" Tools like Tableau or Microsoft Power BI can connect directly to your systems, giving you a live, real-time view of your operational health.

By making performance data visible and accessible to everyone, you foster a culture of accountability. When team members can see how their work directly impacts the KPIs, they become more engaged and proactive in driving improvement.

This focus on measurable output isn’t just some modern business fad; it's a core principle of economic growth. Labour productivity, a key stand-in for operational efficiency, has been a major engine of growth for decades. The OECD's data shows that how well businesses combine labor and capital is a critical factor in long-term success. You can explore more about these global productivity trends and their drivers.

The table below breaks down a few essential KPIs that can get you started.

Essential KPIs for Operational Efficiency

| KPI | What It Measures | Why It's Important | Example Goal |

|---|---|---|---|

| Cycle Time | The total duration of a process from start to finish. | Identifies bottlenecks and opportunities to increase speed. | Reduce order fulfillment time from 48 hours to 24 hours. |

| First Pass Yield | The percentage of units that are completed without any rework. | A direct indicator of process quality and waste reduction. | Increase First Pass Yield for product assembly from 92% to 97%. |

| Throughput | The number of units produced or tasks completed in a given time. | Measures overall process capacity and output volume. | Increase support tickets resolved per agent per day from 25 to 30. |

| Cost Per Unit | The total cost to produce one item or deliver one service. | Provides a clear view of financial efficiency and profitability. | Lower the cost to acquire a new customer by 15% within six months. |

Tracking these metrics gives you a clear, objective picture of your performance, moving you beyond guesswork and into strategic action.

Using Data for Continuous Improvement

Here’s the real secret: the goal of tracking KPIs isn't just to report on what happened last month. It's to fuel what you do next month. Your data is a roadmap pointing you toward your next big win.

For instance, if your cycle time is going down but your error rate is creeping up, that’s a huge red flag. It tells you that you might be sacrificing quality for speed. That’s an insight you can act on immediately to make a precise adjustment.

Get into a regular rhythm—maybe it's a weekly huddle or a monthly review—to go over your KPIs with the team. These meetings shouldn't be about pointing fingers. They should be collaborative problem-solving sessions centered on one simple question: "How can we do even better?" This is how you turn measurement from a boring, passive activity into an active engine for constant improvement.

Common Questions About Improving Operations

Diving into an operational efficiency improvement project can feel a bit overwhelming. It’s natural to have questions pop up about where to even begin, how to get your team on board, and what a "win" actually looks like. Getting solid answers is the first step toward building the confidence to move forward.

Let's cut through the noise and tackle some of the most common questions I hear from leaders trying to make their businesses run better. This isn't about high-level theory; it's about practical, real-world advice to help you get started.

What’s the First Step in Operational Efficiency Improvement?

Before you do anything else, you have to do a deep, honest audit of your current processes. I’ve seen it time and again: leaders get excited about a new piece of software, but without understanding the root problem, they just end up with an expensive tool that doesn't fix anything. You can't improve what you don't truly understand.

A good audit always involves a few key things:

- Mapping out your critical workflows from start to finish. You need to see every single touchpoint and handoff.

- Pinpointing the bottlenecks. Where does work consistently get stuck or slow down?

- Talking to your team. Get direct, unfiltered feedback from the people doing the work day in and day out. They know the process better than anyone.

Once you have this clear, data-driven map of where you are today, you can start plotting a course to where you want to go. Skipping this diagnostic step is probably the number one reason these initiatives don't deliver the results they promise.

How Do I Get My Team to Support These Changes?

This is a big one. You could have the most brilliant plan in the world, but if your team isn't on board, it's dead in the water. The secret is making them part of the solution, not just people the solution happens to. Resistance usually comes from a fear of the unknown or a feeling that change is being dictated from on high.

So, bring them into the fold early and often. Ask for their input during that initial audit—they're your experts on the ground, after all. When you're ready to introduce a change, explain the "why" behind it. Show them how it’s going to make their lives easier, get rid of tedious tasks, and let them focus on more interesting work.

Key Insight: Frame operational changes as a team effort to make everyone's job better, not just a mandate from management. When people feel like they have a voice and can see the personal benefits, they quickly go from being resistant to being your biggest champions.

Which Business Areas Benefit Most from Automation?

While you can find opportunities for improvement almost anywhere, the low-hanging fruit for automation is always in areas bogged down by repetitive, high-volume, rule-based tasks. That's where you'll get the fastest and most noticeable return on your investment.

Take a hard look at departments like:

- Finance: Things like processing invoices, approving expense reports, and entering payroll data are perfect candidates.

- HR: Think about all the paperwork for employee onboarding, managing benefits, or handling time-off requests.

- Customer Service: Automating standard email replies, logging information into your CRM, or routing support tickets can be a game-changer.

When you automate these predictable workflows, you're not just cutting down on human error. You’re also freeing up your best people to tackle the complex, strategic challenges that actually require a human brain. If you want to explore more options, this guide on top strategies to improve operational efficiency is a great resource.

At Zilo AI, we provide the skilled people and AI-ready data solutions needed to bring your operational improvements to life. Whether you're building a team or prepping data for automation, we have the end-to-end support to help your business succeed. https://ziloservices.com